wire edm machine working principle

Wire EDM is a non-conventional machining process which is based on the principle of electrical discharge machining EDM. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that.

Wire Edm Cutting Process With High Precision Ruhlamat

Principle of wire cut EDM.

. It is used for producing hole size less than 01 mm. Electrical Discharge Machining Working Principle What is the basic principle of EDM and how the material is removed in this process. CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo.

As mentioned earlier the EDM process does not require mechanical. It is often used for the production of metal. Holes in the air brakes or.

N 2 PM for newsprint was started up in February 1998. Working Principle of Electrical Discharge Machining Process. If you have any query regarding this article.

Most Wire EDM machines are self-threading meaning that if the wire. To simply put EDM involves removing excess material from a workpiece with the use of thermal energy. Wire filters and other consumables used on wire EDM machines.

An EDM drill uses a tubular electrode to burn a hole through conductive material. This is all about electrical discharge machining principle working equipments advantages and disadvantages with its diagram. Electrical discharge machines work on the principle of material removal using a series of electric Spark discharges occurring between the electrode tool and the.

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. Punch presses uses numerous wire EDM machines fed by a robot. Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process.

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Wire EDM machines require minimal fixturing requirements as compared to other conventional machines. The difference between electrical discharge machining and.

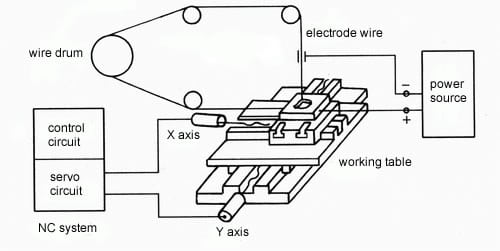

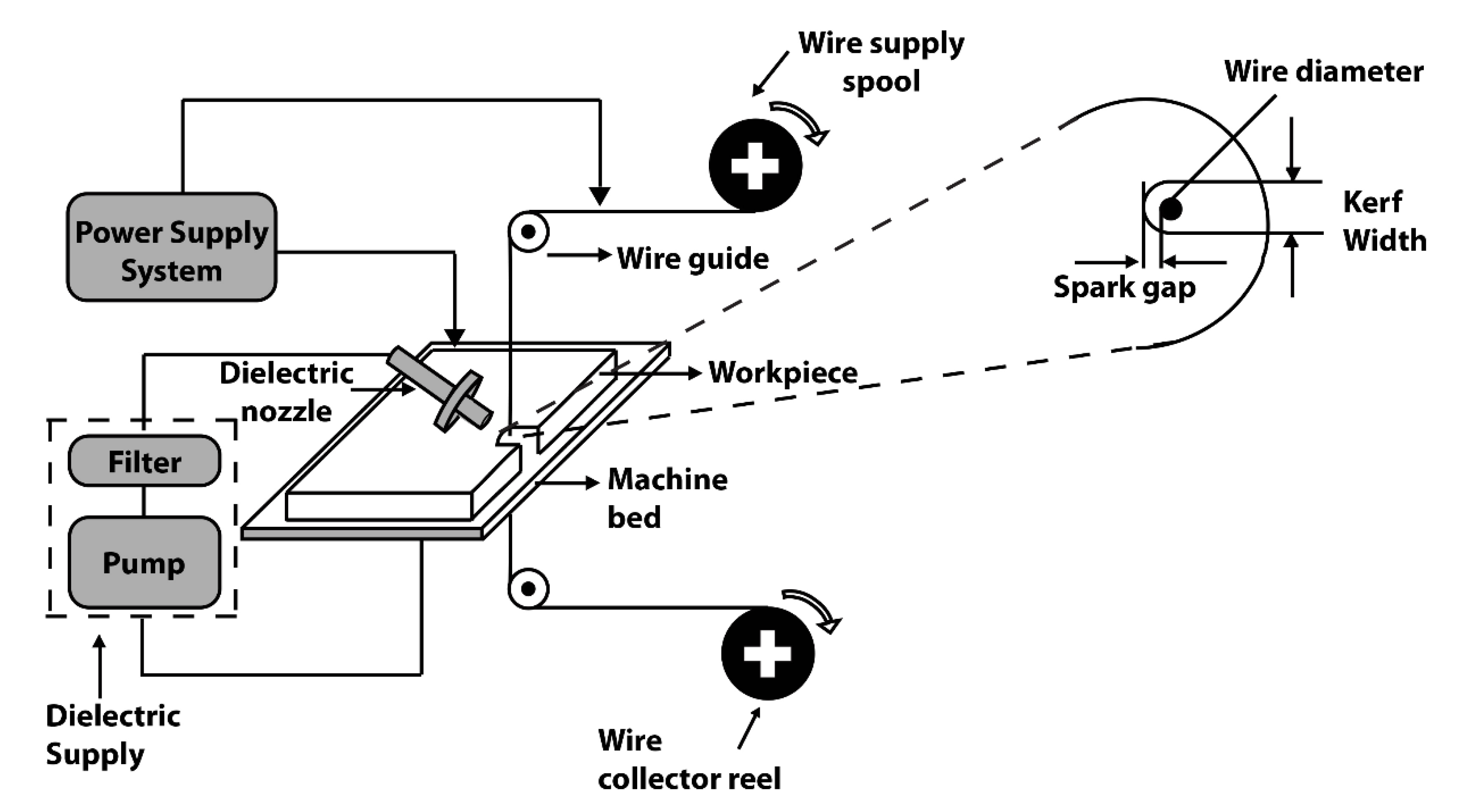

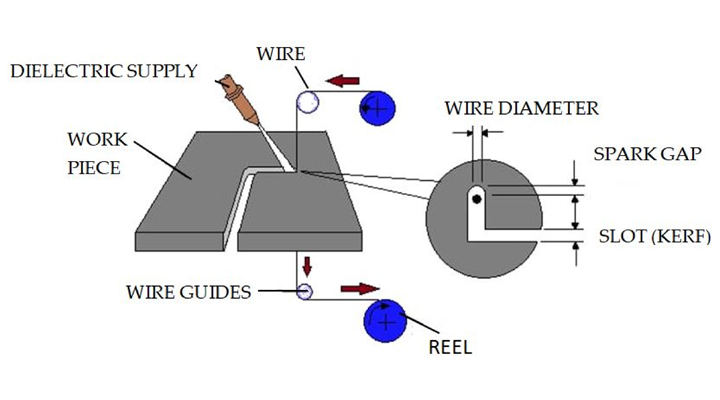

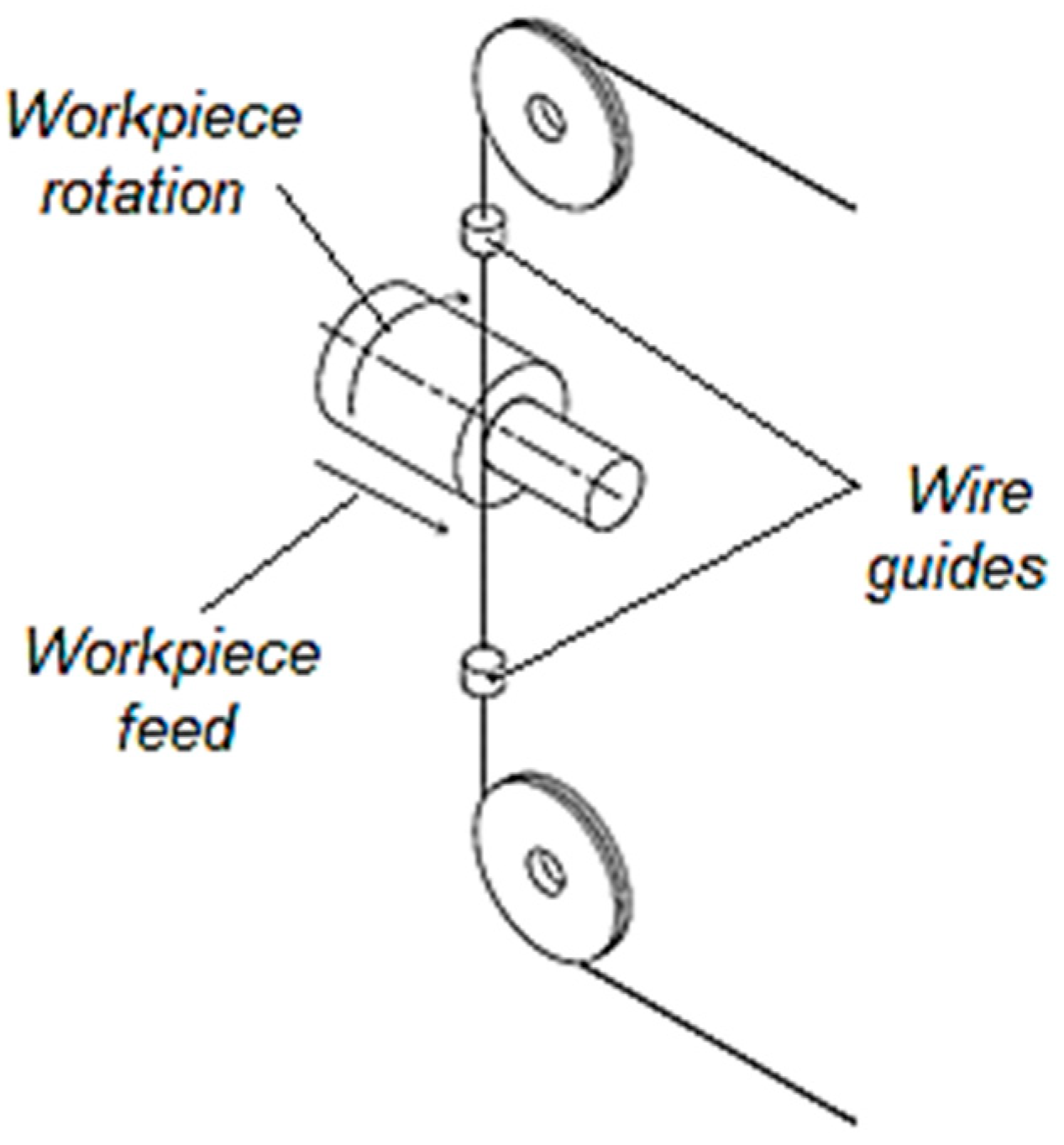

According to the form of the tool electrode and the relative movement between the workpiece and the workpiece the EDM. The deionised water cools the material and washes away the removed particles. The working principle of wire EDM is same as that of conventional EDM except that it uses a small diameter wire about 002 03 mm as electrode and deionized water as.

The Basic Principle Of WEDM. The electrode tool Cathode in the. Wire EDM in process Wire EDM machine.

Ad Faster processing times superior surface finishes for the most complex part geometries. Used for die sinking or die manufacturing. Makino EDMs have a streamlined and efficient interface that helps work get done faster.

A small gap of a calculat. The design speed of this paper machine is max. Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process.

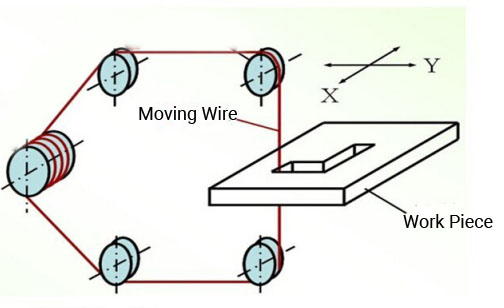

A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the. Wire EDM machining works by creating an electrical discharge between the wire or. Wire electrical discharge machining WEDM uses a metallic wire to cut or shape a workpiece often a conductive material with a thin electrode wire that follows a precisely programmed.

Here are some applications of Electrical Discharge Machining. Wire EDM uses a traveling wire electrode that passes through the work piece. Wire EDM creates a spark in deionised water in which conductivity is highly controlled.

At Nippon Paper Yatsushiro Mill. The wire is monitored precisely by a computer-numerically controlled CNC system. It is suitable for thermoelectric.

Wire EDM which came into commercial use. The Spark Theory on a wire EDM is basically the same as that of the vertical EDM process. Electrical Discharge Machining EDM is a non traditional machining and electro thermal process in which material from the workpiece is removed by using electrical discharges sparks.

The working principle of wire EDM is same as that of conventional.

Jmmp Free Full Text Response Surface Methodology And Artificial Neural Network Based Models For Predicting Performance Of Wire Electrical Discharge Machining Of Inconel 718 Alloy Html

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Edm Machine Video Edm Molding Professional Performance

Wire Ecm Basic Research Platform And Working Space And Kinematic Download Scientific Diagram

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Pdf Manufacturing Of High Quality Miniature Gears By Wire Electric Discharge Machining Semantic Scholar

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Mas 865 How To Make Something That Makes Almost Anything

Wire Edm Guide To Edm Wirecut Machine Process Uses Fine Metalworking

Pdf Review Of Wire Cut Edm Process On Titanium Alloy Semantic Scholar

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

Concord Wire Edm Cutting Machine Download Scientific Diagram

What Is Edm Machining Wire Edm 101 Sans

Sinker Edm Vs Wire Cut Edm What Is The Difference Dek

Machines Free Full Text Wire Electrical Discharge Machining A Review Html